Sanitary womoya diaphragm Pump

Isetshenziswa ezikhathini ezahlukahlukene ezikhethekile ukuhlangabezana nezidingo zabasebenzisi abahlukahlukene.Kusetshenziselwa ukupompa imidiya engeke ishaywe ngamaphampu ajwayelekile futhi izuze imiphumela egculisayo.

Amapharamitha womkhiqizo

| Isibonelo No. |

Ukugeleza (T / h) |

I-Dia. (mm) |

Phakamisa (m) |

Ukuncela (m) |

Ingcindezi Air Ukusetshenziswa Partical Dia. |

isisindo (kg) |

||

|

(mpa) |

(scfm) |

(mm) | ||||||

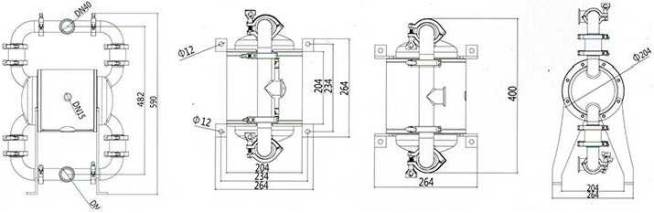

| QBSY5-20 | 0.1-1.8 |

20 |

0-50 |

4.5 |

0.6 |

12.7 |

2.5 |

10 |

| QBSY5-25 | 0.1-1.8 | 25 | 0-50 |

4.5 |

0.6 |

12.7 |

2.5 |

10 |

| QBSY5-32 | 0.1-6 | 32 | 0-50 |

4.5 |

0.7 |

23.66 |

3.2 |

16.8 |

| QBSY5-38 | 0.1-6 | 38 | 0-50 |

4.5 |

0.7 |

23.66 |

3.2 |

16.8 |

| QBSY5-51 | 0.1-12 | 51 | 0-50 | 5.48 |

0.75 |

32 |

5.5 |

33 |

| QBSY5-63 | 0.1-12 | 63 | 0-50 | 5.48 |

0.75 |

12.7 |

5.5 |

33 |

| QBSY5-76 | 0.1-22 |

76 |

0-50 | 5.48 |

0.75 |

12.7 |

6.3 |

54 |

| QBSY5-89 | 0.1-22 |

89 |

0-50 | 5.48 |

0.75 |

12.7 |

6.3 |

54 |

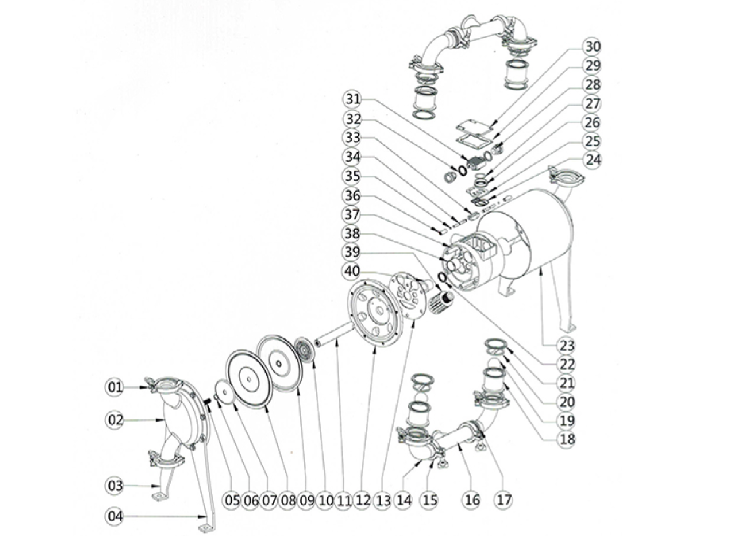

| 1. B Uhlobo Ngocingo | 11. Ukuxhuma i-Rod Shaft | 21. BType Seal | 31. Izingxenye ezinkulu ze-Aluminium Slider |

| 2. Ikholomu | 12. Imigqa | 22. I-V-Ring | 32. V Indandatho |

| 3. Unyawo Lwesobunxele | 13. Gasket Valve Chamber Gasket | 23. Ikhava Yokuvikela | 33. Isilayida Esincane |

| 4. Unyawo Lwesokudla | 14. Ukulayisha okusheshayo | 24. Umhlahlandlela weBlock Gasket | 34. Induku Yokukhuthaza |

| 5. Izikulufu zeplywood | 15. Uhlobo Lokuqinisa | 25. Umhlahlandlela Wokuvimba | 35. Ukuqinisa Induku O-Ring |

| 6. Splint O-Ring | 16.Inlet Futhi Outlet Pipe | 26. Izingxenye zePlastiki ezinkulu | 36. I-Cover Cover Rod |

| 7. Isigaxa Sangaphandle | 17. Indandatho Yokufaka uphawu | 27. Isilayida Esikhulu O-Ring | 37. Igumbi Le-Valve |

| 8. PTFE ulwelwesi | 18. Ibhola Valve | 28. AmaPiston | 38. Umkhono wePiston |

| 9. Ifilimu Elincane | 19. Ibhola Valve | 29. I-Gasket Valve Cover Cover | 39. Umthulisi |

| 10. Isigaxa Sangaphakathi | 20. Ikhava Yesitulo Sebhola | 30. Ikhava ye-Valve | 40. Ukuxhuma Umkhono Wenduku |

Isimiso Esisebenzayo

Iphampu ye-diaphragm yomoya iyimpompo ye-volumetric eletha ushintsho lwevolumu ngokuphindisela emuva ukusonteka kwesifafazi. Isimiso sayo sokusebenza siyefana nepompo ye-plunger. Amapompo e-diaphragm anezici ezilandelayo:

I -Impompo ngeke ishiswe ngokweqile: Ngomoya ocindezelwe njengamandla, ukukhipha kuyinqubo yokwandisa nokumunca ukushisa, ngakho-ke ngesikhathi sokusebenza, izinga lokushisa kwepompo ngokwalo liyancipha futhi akukho gesi oyingozi elikhishwayo.

2-Asikho isizukulwane se-spark: Amaphampu e-diaphragm womoya awasebenzisi amandla kagesi njengomthombo wamandla futhi angavimbela izinhlansi ze-electrostatic ngemuva kokuthi zibekiwe.

I-3.lt ingadlula kuketshezi oluqukethe izinhlayiya: Ngoba isebenzisa indlela yokusebenza ye-volumetric futhi okufakwayo kuyi-valve yebhola, akulula ukuvimba.

4. Amandla okugunda aphansi ngokwedlulele: okokusebenza kukhishwa kusimo esifanayo njengoba kumunxwa lapho iphampu isebenza, ngakho-ke ukuyaluza kwento kuncane futhi kufanele ukudlulisa izinto ezingazinzile.

5. Izinga lokugeleza eliguquguqukayo: I-valve yokugoqa ingafakwa endaweni ephathekayo ukulawula ukugeleza.

Umsebenzi wokuziqhenya.

7. Kungaba idling ngaphandle kwengozi.

I-8.lt ingasebenza ekutsheni.

9. Ububanzi boketshezi obungalethwa bubanzi ngokwedlulele kusuka ku-viscosity ephansi kuya ku-viscosity ephezulu, kusuka ekubhebhethekeni kuya ekuboneni.

10. Uhlelo lokulawula lulula futhi aluyinkimbinkimbi, ngaphandle kwezintambo, amafyuzi, njll.

II Usayizi omncane, isisindo esincane, kulula ukuhambisa.

12.Ukuthambisa kungadingeki, ngakho-ke ukugcinwa kulula futhi akubangeli ukungcoliswa kwendawo yokusebenza ngenxa yokuvuza.

13.lt ingahlala isebenza kahle, futhi ngeke inciphise ukusebenza kahle komsebenzi ngenxa yokugqoka.

14.100% ukusetshenziswa kwamandla. Lapho isitolo sivaliwe, ipompo iyema ngokuzenzakalela ukuvimbela ukuhamba kwemishini, ukugqoka, ukulayishwa ngokweqile, kanye nokukhiqizwa kokushisa.

Ayikho uphawu olunamandla, ukulungiswa kulula, ukuvuza kuyagwenywa, futhi alikho iphuzu elifile lapho usebenza.