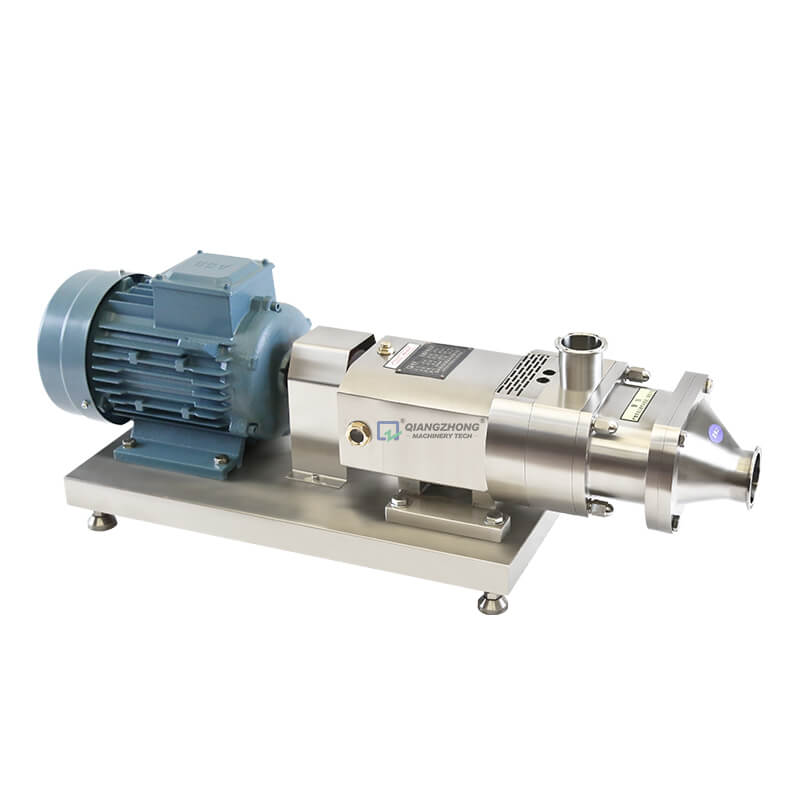

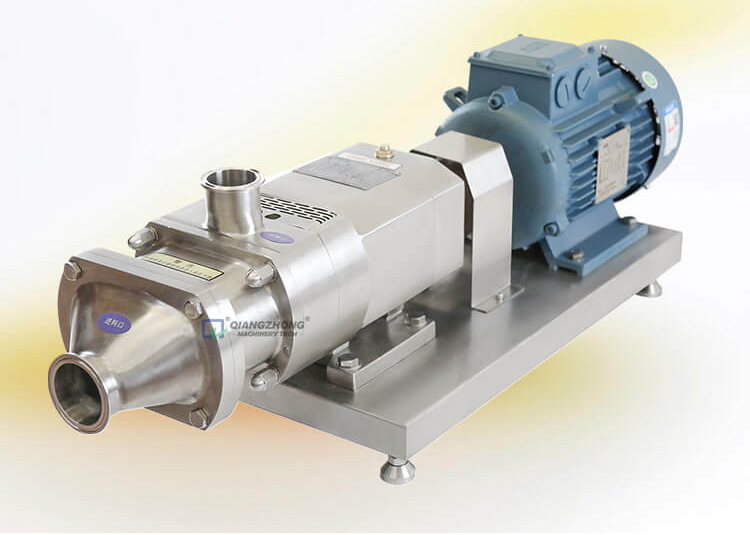

Ukwakhiwa Komkhiqizo

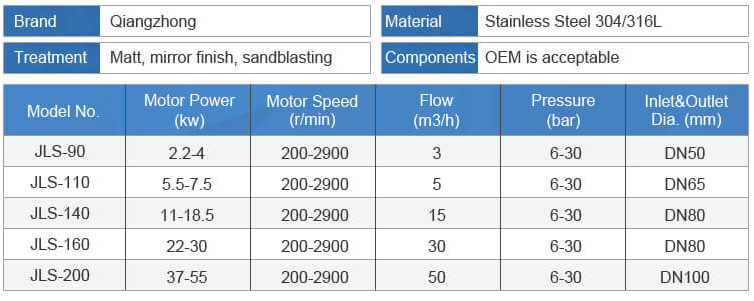

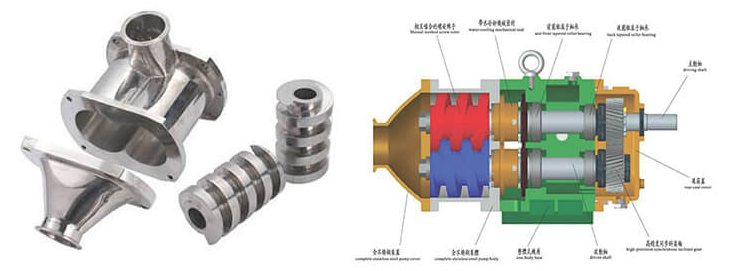

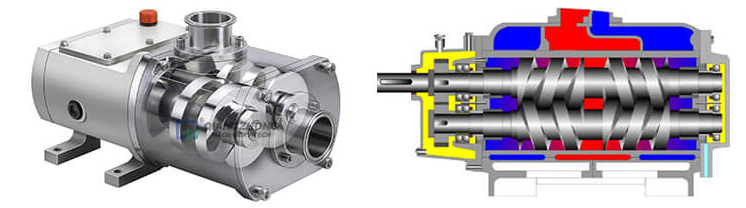

Iphini lokuhambisa iphini le-Twin lisebenzisa isakhiwo senhlanzeko evulekile neyesimo. Lonke uhlelo luqukethe izingxenye ezintathu eziyinhloko: umzimba wepompo, ibhokisi lokuhambisa igiya nemoto. Ngokuhambisana ne-standard yensimbi engenasici engenasici, zonke izingxenye ezixhumana nezinto zenziwe ngensimbi engenasici ephezulu futhi ephezulu engu-304 / 316L. Izingxenye zokudlulisa zenziwe ngezinhlobo ezintathu zezinto zokwakha: i-spheroidal graphite, insimbi yensimbi kanye nensimbi engagqwali ukugcina izinga eliphakeme nekhwalithi ephezulu yemishini. Umzimba wepompo, oyingxenye eyinhloko yohlelo lonke, uqukethe ikhava yegumbi langaphambili, umgodi, i-rotor evunguza, idrayivu shaft, indawo ebiyelwe ngomshini, nophawu lomshini. Idrayivu shaft yamukela idizayini eqinile eqinisiwe enesakhiwo somzimba esihlanganisiwe, futhi kusetshenziswa ikhwalithi ephezulu, enamandla aphezulu okwehlisa imishini yensimbi engagqwali, eqinile-encibilikisiwe.

U-gearbox uyingxenye ebalulekile yohlelo lonke. Uhlelo lwayo lokuhambisa amandla luqukethe idrayivu shaft kanye ne-shaft eqhutshwa, zombili ezifakwe imikhono yesikulufu. Inqubo yokudlulisa ifezwa ngokusebenzisa igiya lokuvumelanisa elifakwe maqondana ne-drive shaft, futhi igiya lisebenza ngokunemba okuphezulu kwamagiya asetshenziswayo (esikhundleni sokukhuthaza amagiya anomsindo omkhulu nokudlidliza) ukuqinisekisa ukuthi uhlelo lusebenza ngokushelela, buthule, nangokuzwana okukhulu futhi ngobuntu. Ibhokisi legiya lenziwe nge-spheroidal graphite, insimbi yensimbi nensimbi engagqwali, eqhubeka ithuthukise izinga lempilo nokusebenza kohlelo lwemishini. Idrayivu shaft isebenzisa idizayini eqinile, futhi amabheringi wokudlulisa asebenzisa kuphela amandla aphakeme, ikhwalithi ephezulu, ukusebenza okuphezulu kwemikhiqizo edumile emhlabeni jikelele. Ukusebenza kokugcoba kokugcoba okuphezulu kusebenza ngokuqhubekayo kuqinisekisa ukuthi uhlelo lungakwazi ukubhekana nezimo ezingalindelekile futhi ngaleyo ndlela lube nempilo ende yokusebenza.

Isimiso Esisebenzayo

Amapheya wesistimu wokuvunguza aklanywe ngokukhethekile, enza uchungechunge lwesikhala esinamandla sokufaka uphawu phakathi kwabo. Ngenxa yokuvalwa kokuvunguza nokulingana okuseduze kokuvunguza nodonga lwangaphakathi lwe-liner, kwakheka uchungechunge lwezikhala eziningi ezivalwe phakathi kokungena nokudonswa kwephampu. Ngokuzungezisa nokuzibandakanya kwesikulufa, kwakheka isikhala sophawu oluqhubekayo ekugcineni kokumunca kwepompo, uketshezi olusegumbini lokuncela luvalwe kulo, futhi luqhutshwa ngokuqhubekayo egumbini lokuncela kuye ekugcineni kokukhipha ohlangothini lwe-axial spiral . Ikhipha ngokuqhubekayo nangokungenamkhawulo uketshezi oluvalelwe ezikhaleni ezihlukene, kube sengathi amantongomane aqhutshelwa phambili ngokuqhubekayo ngenkathi kuvunguza ukujikeleza. Lesi yisisekelo sokusebenza esiyisisekelo salolu chungechunge lwempompo yamawele.

Parallel ukufuduka futha has 5 uchungechunge kanye 30 onobuhle imikhiqizo ehlukene.

◎ Amakhasimende angakhetha ikhambi lesicelo elihamba phambili ngokuya ngenqubo yokukhiqiza nesimo somkhiqizo.

Range Pump processing processing flow range: 0-145 m3 / h

Difference Umahluko wengcindezi phakathi kokungena kwepompo kanye nendawo esidayiswayo: Imvamisa imigoqo engu-6-8, kuze kufike kuma-26 bar

Speed Ijubane lempompo: likwazi ukuguquguquka ngokukhululeka, kuze kufike ku-2 900 rpm

◎ viscosity sepompo ehambisa izinto: kufika ku-2,000,000 cSt (cps)

Inkomba yokujikeleza kwepompo: iyaguquguquka njengoba kudingeka

Range Ibanga lokushisa elisebenza ngempompo: kufika ku-150 ° C.

Kunezindlela ezi-3 zokuxhuma, okungukuthi ukuxhumana ngocingo, ukuxhumana ngentambo nokuxhuma kwe-flange. Indlela yokuxhuma ezenzakalelayo ukuxhuma kocingo.

Umbukiso Womkhiqizo