Amapharamitha womkhiqizo

Isingeniso Somkhiqizo

Iphampu yesikulufa iyamunca futhi idedele uketshezi ngokuzungezisa isikulufa. Isikulufa esiphakathi yisikulufa esisebenzayo, esiqhutshwa ngumgqugquzeli oyinhloko. Izikulufo ezinhlangothini zombili ziyizikulufo eziqhutshwa, futhi zijikeleza zibuyela emuva ngesikulufa esisebenzayo. Zombili izintambo ezisebenza futhi eziqhutshwa isikulufu ziphela kabili. Ngenxa yokuvalwa kokuvunguza nokulingana okuseduze kokuvunguza nodonga lwangaphakathi lwe-liner, kwakheka uchungechunge lwezikhala eziningi ezivalwe phakathi kokungena nokudonswa kwephampu. Ngokuzungezisa nokuzibandakanya kwesikulufa, kwakheka isikhala sophawu oluqhubekayo ekugcineni kokumunca kwepompo, uketshezi olusegumbini lokuncela luvalwe kulo, futhi luqhutshwa ngokuqhubekayo egumbini lokuncela kuye ekugcineni kokukhipha ohlangothini lwe-axial spiral . Ikhipha ngokuqhubekayo nangokungenamkhawulo uketshezi oluvalelwe ezikhaleni ezihlukene, kube sengathi amantongomane aqhutshelwa phambili ngokuqhubekayo ngenkathi kuvunguza ukujikeleza. Lesi yisisekelo sokusebenza esiyisisekelo salolu chungechunge lwepompo yesikulufu esiphindwe kabili.

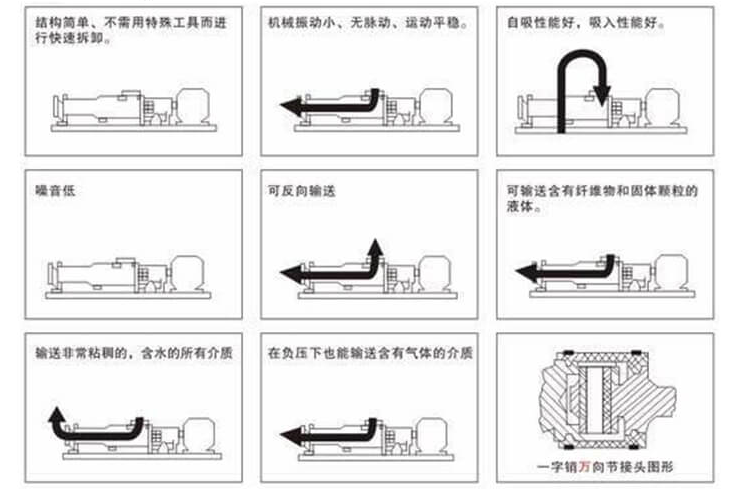

Intulo Pump Izici:

I-1.Umugqa wokuvala ongahlangana ne-Rotor ye-stator wehlukanisa ngokuphelele igumbi lokuncela egumbini lokukhipha, ukuze ipompo libe nomsebenzi ofanayo njenge-valve;

Ingakwazi ukuletha imidiya enezigaba eziningi zoketshezi, igesi nokuqina.

Umthamo awuguquki lapho uketshezi olukumpompo lugeleza, akukho kunyakaza okuyisiphithiphithi nokuphefumula;

I-4.Igumbi levolumu elenziwe yi-stator nokunwebeka linganciphisa ngempumelelo ukugqoka kwendawo okuqukethe izinhlayiya eziqinile;

5.I-viscosity ephakathi nendawo efinyelela ku-50: 000Mpa s, okuqinile kuze kufike ku-50%;

Izinga lokugeleza lilingana nejubane, futhi nombusi, lingalungisa ngokuzenzakalela ukugeleza, futhi kokubili ukulethwa phambili nokubuyela emuva kuvunyelwe.

Iphampu yesikulufa inezinzuzo ezilandelayo:

• Uma kuqhathaniswa nepompo ye-centrifugal, ipompo yesikulufa ayidingi ukufaka i-valve, futhi ukugeleza r kudle ukugeleza okuqinile okuzinzile;

• Uma kuqhathaniswa nepompo ye-plunger, impompo yesikulufa inekhono elinamandla lokuziphakamisa nokuphakama kokudonsa okuphezulu;

• Uma kuqhathaniswa nepompo ye-diaphragm, ipompo yesikulufu ingathutha zonke izinhlobo zokungcola okuxubekile, okufana negesi equkethe okuphakathi nendawo nezinhlayiya eziqinile noma imicu, futhi ingahambisa nezinto ezahlukahlukene ezonakalisayo;

• Uma kuqhathaniswa namaphampu egiya, amaphampu wokujiya angaletha imidiya enesithunzi;

• Ngokungafani namaphampu e-piston, amaphampu e-diaphragm kanye nama-gear pumps, amaphampu we-screw angasetshenziselwa ukugcwalisa nokulinganisa imishanguzo.

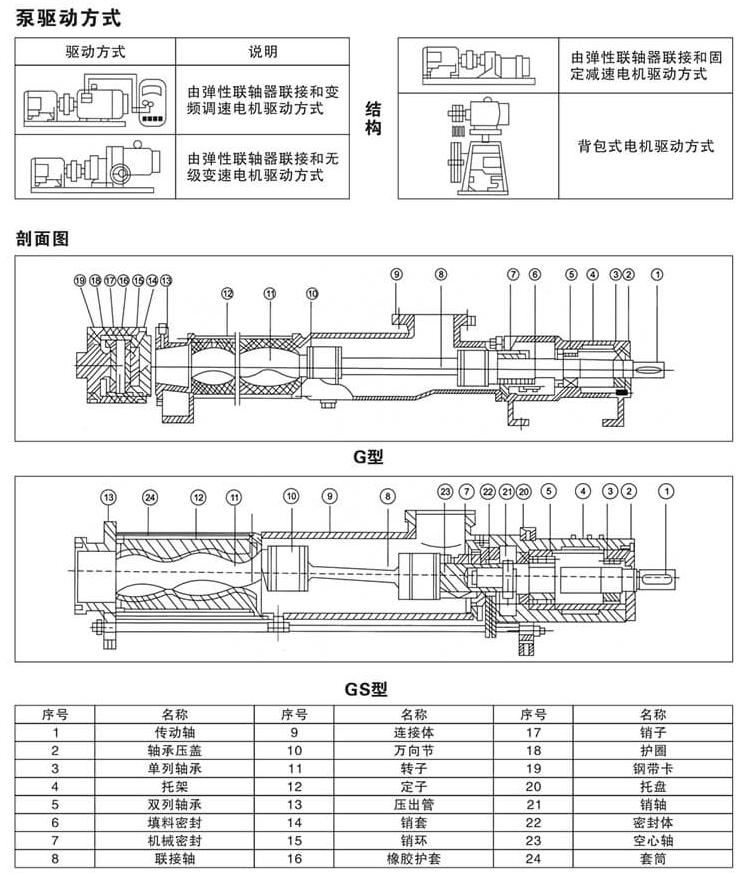

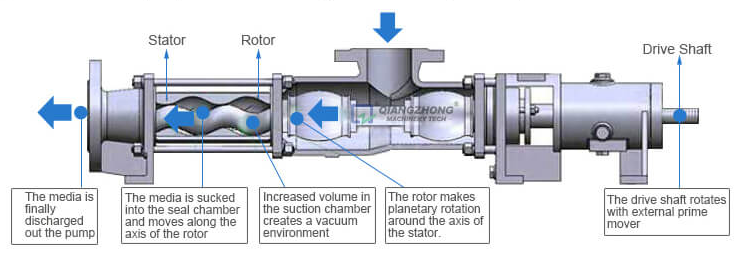

Isimiso Esisebenzayo

Iphampu yesikulufu yipampu yohlobo lokushintshelwa. Izingxenye eziyinhloko yi-Rotor ne-stator. I-Rotor iyisikulufu esine-lead-lead enkulu, esinamazinyo amakhulu, nesincane-helix yangaphakathi-ububanzi, kanti i-stator ifana nokuvunguza nekhanda elinamakhanda amabili, okwakha isikhala sendawo yokugcina phakathi kwe-Rotor ne-stator . Lapho i-rotor isebenza ku-stator, okumaphakathi kuhamba ngokuxhuma ukusuka ekugcineni kokuncela kuye ekuhambeni kokukhipha.

Iphampu yesikulufa inezinzuzo ezilandelayo:

I .A ezahlukene ingcindezi flow. Ingcindezi imayelana no-3.4-340 kgf / cm2 kanti izinga lokugeleza lingu-1,8600 cm3 / m;

Uhlu olubanzi lwezinhlobo nama-viscosities oketshezi oluhanjiswa;

I-3.Inejubane elikhulu ngenxa yamandla aphansi we-inertia wezingxenye ezijikelezayo kupompo

Ngekhono lokuziqhenya, ukusebenza okuhle kokudonsa ,;

Ukugeleza okungafani, ukudlidliza okuphansi, umsindo ophansi;

Ukuzwela okungatheni kumagesi angenayo nokungcola kuqhathaniswa namanye amaphampu ajikelezayo,

7.A isakhiwo esiqinile, ukufakwa lula kanye nokugcinwa.

Okubi kwephampu yesikulufu ukuthi isikulufa sidinga ukucutshungulwa okuphezulu nokuhlangana; ukusebenza kwepompo kuyazwela kuzinguquko ku-viscosity ye-liquid.

Umbukiso Womkhiqizo

Amaphutha ajwayelekile nezixazululo

1 Iphampu ayisebenzi:

Izimbangela ezingaba khona: Irotor ne-stator ziqinile kakhulu; i-voltage iphansi kakhulu; i-viscosity yesilinganiso iphakeme kakhulu.

Isixazululo: Zungezisa ipompo amahlandla ambalwa ngamathuluzi nangabasebenzi, lungisa ingcindezi; hlaziya abezindaba.

2.Impompo ayiphumi:

Izimbangela ezingaba khona: ukuqondisa okungalungile kokujikeleza; izinkinga nge-tube yokudonsa; viscosity eliphezulu kakhulu medium; i-rotor, i-stator, noma izingxenye zokudlulisela zilimele;

Isixazululo: Lungisa ukuqondisa kokujikeleza; hlola ukuvuza, ama-valve wokungena nawokuvula; thela imithombo yezindaba; hlola bese ushintsha izingxenye ezonakele;

Ukuntuleka kokugeleza:

Izimbangela ezingaba khona: amapayipi avuzayo; ama-valve angavuleki ngokugcwele noma avinjwe ingxenye; isivinini sokusebenza esiphansi; ukugqoka ama-rotors nama-stators.

Isixazululo: Hlola futhi ulungise amapayipi; vula onke amasango, susa ama-plugs; lungisa ijubane; shintsha izingxenye ezilimele

4.Lack ingcindezi:

Izimbangela ezingaba khona: I-Worn rotor ne-stator.

Isixazululo: Faka esikhundleni se-rotor, i-stator

Ukushisa kwe-5.Motor:

Izimbangela ezingaba khona: ukwehluleka kwezimoto; ingcindezi yokuphuma ngokweqile, ukulayisha ngokweqile ezimotweni, nomonakalo othwala izimoto. Isixazululo: Hlola imoto bese uyayixazulula; shintsha ingcindezi yokulungisa i-valve yokuvula; buyisela ingxenye eyonakele.

Ingcindezi 6.Flow lehla kakhulu:

Izimbangela ezingaba khona: Ukuvaleka okungazelelwe noma ukuvuza kwesekethe; ukugqoka okungathí sina kwe-stator; ushintsho olungazelelwe ku-viscosity ye-liquid; ukwehla okungazelelwe kwamandla kagesi.

Isixazululo: Susa ishubhu exhunyiwe noma evaliwe; shintsha i-stator rubber; shintsha i-viscosity ye-fluid noma amandla we-motor, lungisa i-voltage

Inombolo enkulu yoketshezi oluvuzayo kushaft seal: Izimbangela ezingaba khona: Isixazululo sokugcwalisa okuthe xaxa Isixazululo: Cindezela noma ubeke okunye okugcwalisayo.

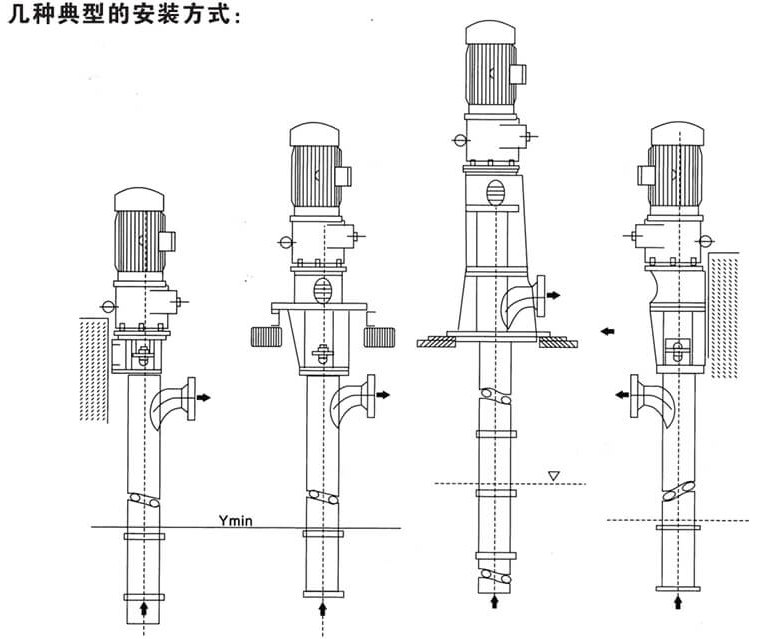

Imiyalo Yokufaka

• Naka ukuqondisa kokujikeleza kwemoto ukuvimbela ukujikeleza okuphindayo.

• Ipayipi okulula ukulisusa elinobude obukhudlwana kune-stator kufanele lifakwe ngaphambi kwento ehambisa uketshezi ukuze kube lula ukushintshwa kwe-stator.

• Gcina okufakwayo kwepompo kuqonde mpo, indawo okuvela kuyo ohlangothini oluvundlile, ukuze uphawu lusebenze esimeni sengcindezi, kunciphise ingcindezi yegumbi elivalwe. Ukuzungezisa: ukuzungezisa okuphikisana nokuhamba kwewashi njengoba kubonakala ekuphumeni. Amapayipi kufanele asethwe ukuxhasa amaphuzu, ngoba ukungena kwepompo nama-flanges (amapayipi) empompo awakwazi ukumelana nesisindo sepayipi.

• Ipayipi kufanele lihlanzwe ngaphambi kokufakwa ukuze kuvinjelwe izinto zangaphandle ekulimaleni i-stator ne-rotor futhi kudale ukuvimba.

• Ububanzi bepayipi kufanele bufananiswe nobubanzi bepompo ngangokunokwenzeka. Ububanzi obuncane be-inlet buzobangela ukungabi bikho kwepompo okwanele, okuzothinta ukukhishwa kwepompo kanye nengcindezi yokukhipha. Ezimweni ezinzima, kuzoholela ekudlidlizeleni kwepayipi nasekulimaleni kokuqala kwe-stator. Amapayipi amancane kakhulu okukhipha amanzi azoholela ekulahlekelweni kwengcindezi yokuphuma.

• Ngezimpawu zamashafula anezimpawu zemishini, engeza amanzi amasha, uwoyela wokuthambisa, noma okunye okupholisa.

Okwezimpawu zamashaft ezivaliwe ezingashadile, uma okulethwayo okuphakathi kuyisikhuthazi, okuqina kalula futhi okukhanyisiwe, uphawu lomshini kufanele luhlanzwe ngemuva kokuthi ipompo liyekile ukusebenza ukuqinisekisa ukusebenza okujwayelekile kophawu lokukhanda. Uhlangothi ngalunye lwebhokisi lesibonakaliso lune-interface yensimbi yepayipi lentiyintshi, futhi ukufakwa kwe-outlet throttling kufakiwe. Umugqa wokungena woketshezi olujikelezayo uxhunywe ngqo ebhokisini lezimpawu. Ngasohlangothini lwayo lokuphuma, ukufakwa kwe-outlet throttling (okubaluleke kakhulu ekugcineni ingcindezi ethile ebhokisini le-sealability) bese kuxhunywe kulayini ophumayo. Lapho ufaka inkanyezi emshinini, uketshezi olujikelezayo kufanele luqale kuqala, bese uvula ipompo; lapho kumiswa, kufanele kufakwe ipompo kuqala, bese kucisha uketshezi olujikelezayo.